Green Paper, Issue 1—2025

Closing the loop:

Creating circular products with OrganoClick technologies

Download as PDF

Executive Summary

As the world faces increasing environmental challenges, the need to transition from a wasteful linear economy to a sustainable circular economy has never been more urgent. Traditional “take-make-waste” systems are depleting natural resources and harming ecosystems, but innovative solutions are paving the way for change. By prioritizing recyclability before biodegradability, materials can have a longer life cycle while minimizing their environmental impact.

OrganoClick is at the forefront of this transformation, designing bio-based, biodegradable, and re-cyclable solutions that align with nature’s own processes. From high-performance, fluorocarbon-free textile treatments to biodegradable nonwoven binders, OrganoClick’s innovations are closing the loop on sustainability. Through scientific advancements and smart material design, the company ensures products break down safely at the end of their life, leaving no harmful residues behind.

This article explores how thoughtful product design and new innovations can create a future where waste becomes a resource and circularity is the norm.

Introduction

In an era of growing environmental challenges, the need for a shift from a linear economy to a circular economy has become increasingly urgent. A circular economy emphasizes the sustainable use of resources by designing products and processes that minimize waste, maximize resource efficiency, and enable materials to be reused or recycled.

The problem with linear systems

We only have one planet Earth, but we consume material as if there are several more. The raditional linear economic systems which operate on a “take-make-waste” model, where resources are extracted, processed into products, and discarded after use, are devastating for the ecosystem that we live in. This model has led to resource depletion, environmental degradation, and a growing waste crisis. 90% of the biodiversity depletion comes from resource extraction and processing[1].

Products designed for disposability often contain non-biodegradable materials and harmful chemicals, making them difficult to recycle or safely decompose. The environmental cost of this approach has reached critical levels, demanding a systemic change in how products are designed, manufactured, and disposed of.

The sustainable practice for all material designs, especially for disposables such as packagings and wipes, should prioritize recyclability before biodegradability. A material should be designed to be able to be recycled multiple times, extending its useful life and reducing the demand for virgin resources. Only when it is no longer possible to recycle the material should it be capable of degrade naturally in environments such as in soil or home composting, ensuring minimal environmental impact.

Paper fibers provide an excellent example of this principle. High-quality paper can be recycled several times, with fibers gradually shortening in each cycle. As the fibers weaken and can no longer be reused in the recycling stream, they are able to degrade safely in natural environments. In a home compost system, properly produced paper products break down into organic matter, enriching the soil without leaving harmful residues.

Designing for end-of-life and the role of innovation for closing the loop

A critical aspect of circularity is designing products with their end-of-life in mind. As much as 80% of a product’s environmental impact is determined during the design phase[2]. While designing a product aiming at macroscopic properties, there need to be a deep understanding of its molecular structure. Moreover, one needs to consider both where the raw materials come from as well as where they might end up after usage. Therefore, knowledge of the area of application is very crucial.

Most plastic material, as we know them, will not degrade in nature. These plastics can only be permanently removed with incineration or pyrolysis[3], meaning that most plastics ever made which have not been destroyed thermally still exist in some form on the planet.

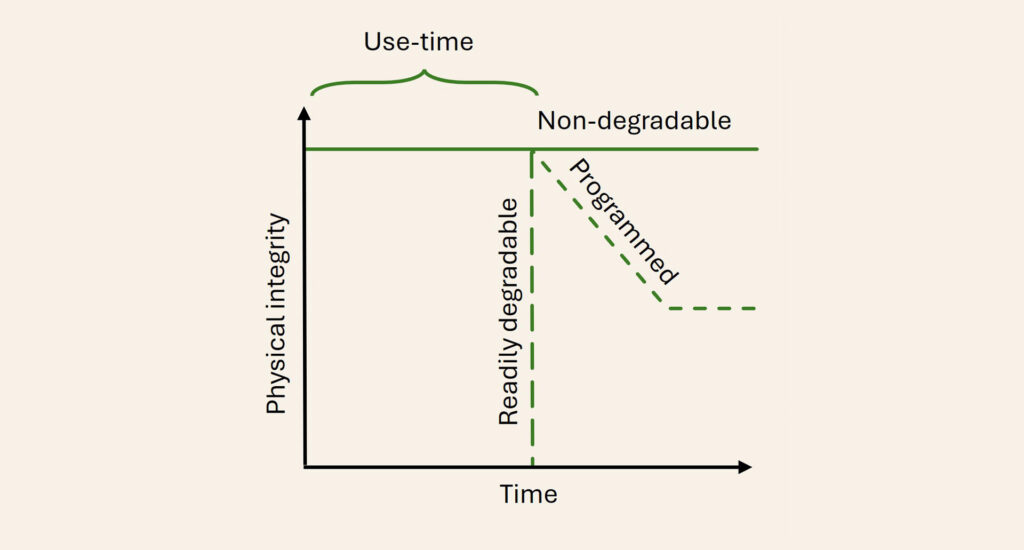

On the other hand, when a material is readily biodegradable, it will self-destruct when its lifetime is over and the environment changes. After fulfilling its intended period of useful service, while maintaining all its originally formulated properties, it naturally breaks down and its components are used by the microorganisms surrounding it in the nature. This process allows it to return to the ecosystem in an environmentally friendly way[4]. Figure 1 explains this practice.

Figure 1. The intrinsic property of degradation when the use time is over.

Biobased, biodegradable, and compostable?

The three terms are often mixed up and confused but are actually described by distinct material properties. Biobasedrefers to materials derived wholly or partially from biomass, such as plants or microorganisms. However, biobased materials are not necessarily biodegradable or compostable. Biodegradable means that a material can be degraded by microorganisms into natural elements like water, carbon dioxide, and biomass under specific environmental conditions. The rate and completeness of degradation depend on factors such as temperature, moisture, and microbial activity. Compostable materials are a subset of biodegradable materials that meet stricter criteria, degrading within a defined timeframe under controlled composting conditions, leaving no toxic residues. Industrial composting often requires elevated temperatures, while home composting occurs at ambient conditions and may take longer time. Understanding these distinc-tions is critical when assessing environmental impact and end-of-life strategies for materials.

Degradation in different environments

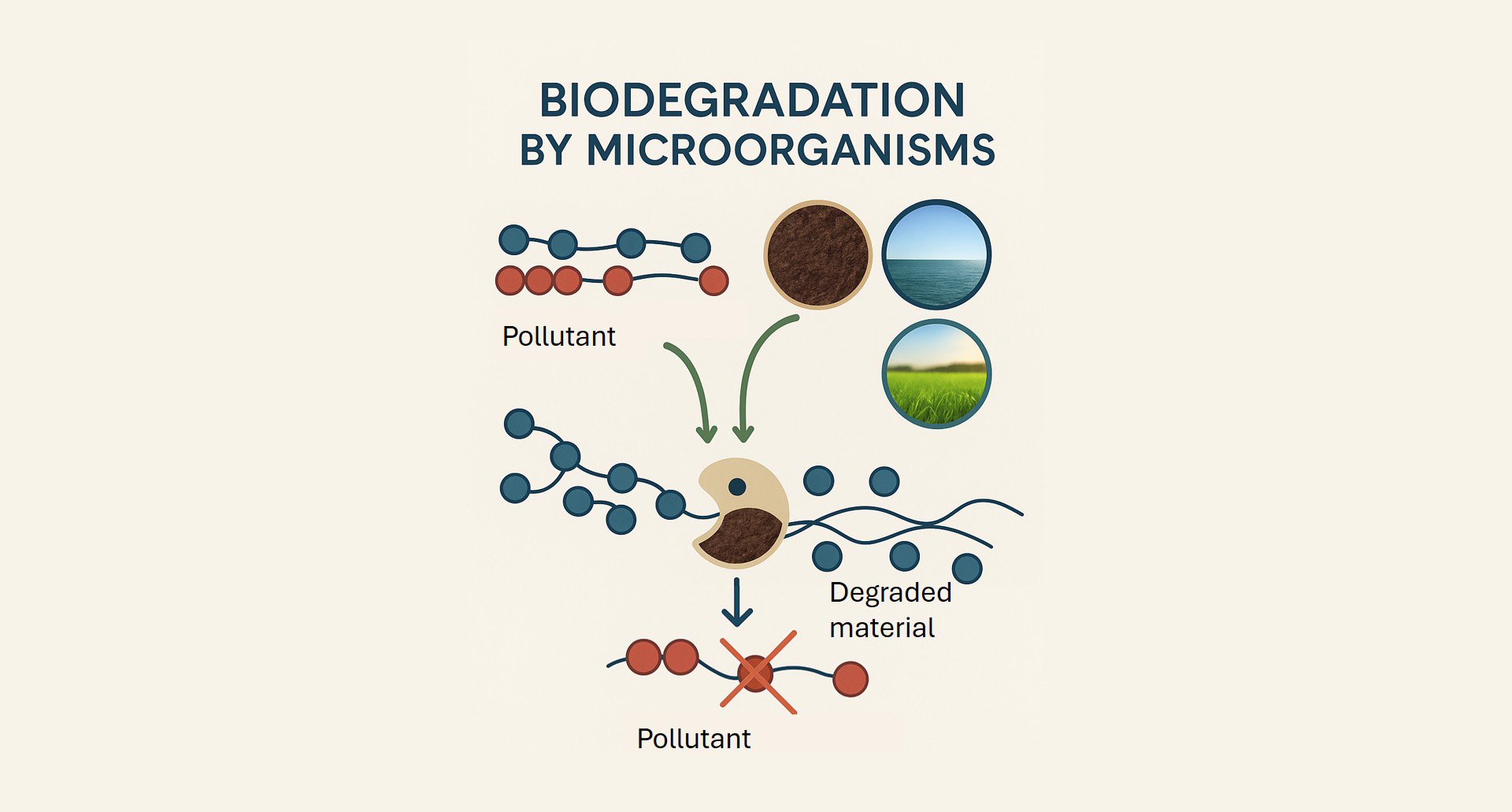

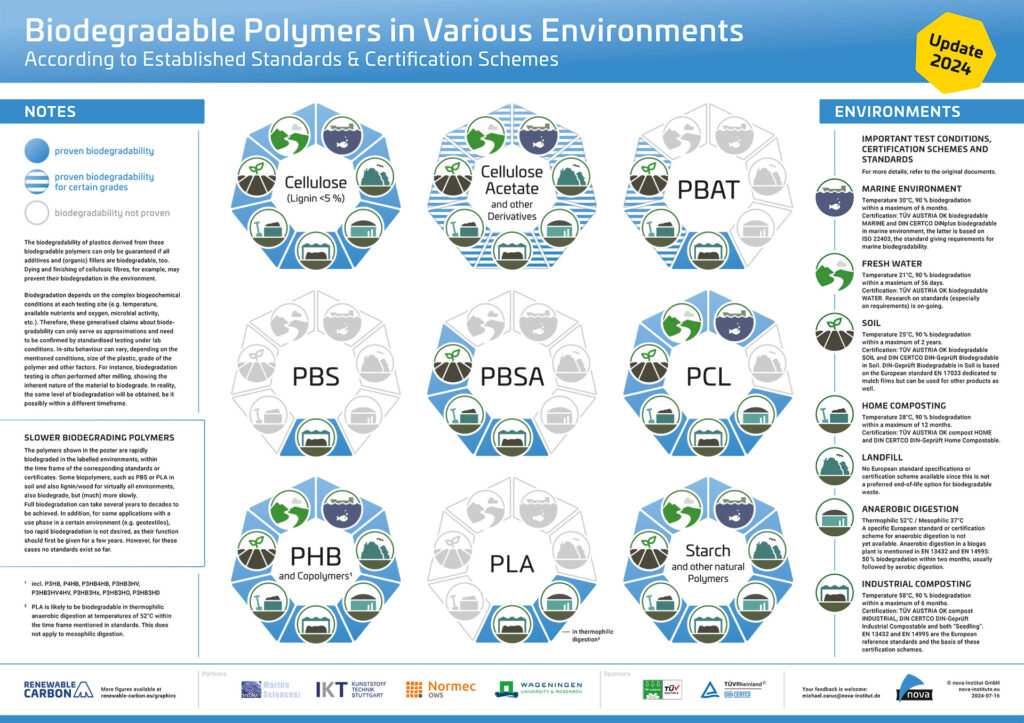

Different environments will handle the degradation of structures differently (Figure 2)[5]. A polymer that breaks down in soil might not degrade if it ends up in the ocean, and industrial compositing conditions are not using the same conditions as can be found in home compost.

Figure 2. Type of material and environment decides the biodegradation.

Biodegradability refers to the ability of a material to break down into natural elements such as carbon dioxide, water, and biomass with the help of microorganisms. However, different environments such as soil, marine water, home compost, and industrial compost have distinct conditions that influence the rate and extent of bio-degradation. Moreover, a product that is biodegradable can be decomposed by microorganisms, but this does not automatically mean that it will break down into high-quality compost suitable for soil enrichment[6]. Consequently, different testing methods and certifications exist to assess materials in these specific conditions.

Soil biodegradability depends on moderate oxygen availability, varied microbial communities, fluctuating temperature, and moisture levels. The test periods can range from six to twenty-four months.

Marine biodegradability is influenced by low oxygen and nutrient availability, high salinity, and cooler temperatures, leading to slower degradation rates. Testing in marine environments can take up to twelve months.

Home compostability is subject to lower and fluctuating temperatures, less controlled moisture, and aeration. The microbial activity varies due to non-uniform household composting practices, and the decomposition timeframe typically ranges from three to twelve months. No hazardous compounds are allowed to be found during the degradation process.

Industrial compostability, on the other hand, occurs in high-temperature environments ranging from fifty to seventy degrees Celsius, with optimized moisture and aeration that enhance microbial activity. The composting process in these settings usually takes ninety to one hundred eighty days and follows strict disintegration and chemical safety criteria. Other types of environments with standardized conditions are fresh water, landfill and anaerobic digestion.

Figure 3 shows one of the world’s leading posters on biodegradability, a comprehensive and educative information about different biomaterials on the market and how they pass or fail each biodegradability test.

Figure 3. A comprehensive comparison of different biobased materials and their degradation in various environments (nova-Institute 2024[7]). Download figure 2 in high-res.

OrganoClick’s commitment to circularity

OrganoClick addresses these issues by rethinking material design at its core. Our technologies and products are based on renewable raw materials that enhance biodegradability and recyclability. This approach ensures that products can integrate into natural cycles as well as recycling streams, mimicking the waste-free systems of nature.

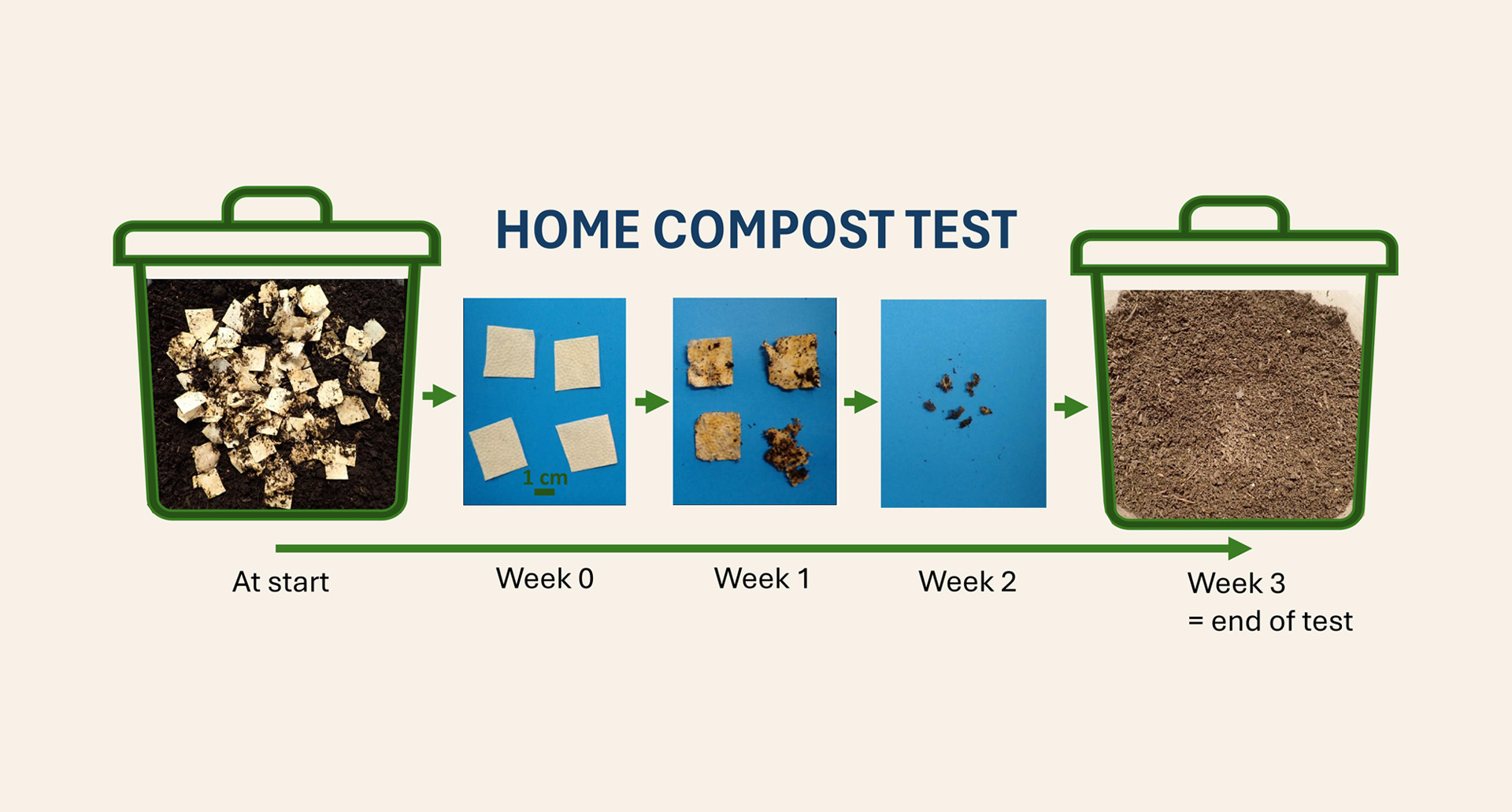

All our commercial nonwoven binders are tested according to OECD 301 to ensure biodegradation in sewage systems conditions, and some types are also certified TÜV OK compost HOME, ensuring that all carbon are breaking down as fast as a cellulose standard in a home compost, and that the soil does not contain any harmful substances after the complete degradation. Unlike traditional binders, who create a composite with cellulosic fibers making incineration as only end-of-life option, OrganoClick’s biobased binders support the recovery and reuse of the valuable cellulose fibers once the nonwoven product’s lifetime is over. The degradation of nonwoven composed of cellulose pulp and OC-Biobinder® from a standardized disintegration test in compost at ambient conditions is visually represented in Figure 4.

In the textile area, OrganoTex® has revolutionized water-repellent treatments by eliminating fluorocarbons, which are particularly persistent pollutants, and plastic polymers that are used as replacements to fluorocarbons in many water repellent products. OrganoTex®-treated fabrics maintain their high performance while having a biodegradable finishing agent, ensuring they do not contribute to microplastic pollution when disposed of, or when the finishing agent is wear and tear during use of the garment. This innovation enables the fashion, shoe and outdoor industries to meet consumer demand for sustainable, high-performance products while reducing their ecological footprint.

Figure 4. Nonwoven made of cellulose fibers (65%) and OC-Biobinder® Lily 145X (35%) at start and after 1, 2 and 3 weeks of composting at ambient temperature.

[1] https://environment.ec.europa.eu/topics/circular-economy_en

[2] https://environment.ec.europa.eu/topics/circular-economy_en

[3] Geyer, R., Jambeck, J. R., & Law, K. L. (2017). Production, use, and fate of all plastics ever made. Science Advances, 3(7), e1700782–e1700782. https://doi.org/10.1126/sciadv.1700782

[4] Stevens, E. S. (2001). Green Plastics. Princeton University Press.

[5] Zumstein, M. T., Narayan, R., Kohler, H.-P. E., McNeill, K., & Sander, M. (2019). Dos and Do Nots When Assessing the Biodegradation of Plastics. Environmental Science & Technology, 53(17), 9967–9969. https://doi.org/10.1021/acs.est.9b04513

[6] https://okcert.tuvaustria.com/ok-biodegradable-en/

[7] https://renewable-carbon.eu/publications/product/biodegradable-polymers-in-various-environments-according-to-established-standards-and-certification-schemes/